How To Select Your Finish?

Common Finish For Cards

- Common glossy lamination

Gloss lamination, also known as PP lamination or POP lamination, has the potential to provide a stunningly brilliant and eye-catching finish. We advise using it for card and box fronts with a mostly pastel color scheme (pink, white, etc.). It can be used to prevent fading, water damage, rubbing and scratching, and more, however, it cannot be used in conjunction with the edging finish.

- Common matte lamination

Prints that have been matte laminated seem professional and soft. Further, its potential to create a more natural, minimalist, and elegant sense is facilitated by its lack of a reflecting surface. Matte lamination, in comparison to glossy lamination, tends to last longer. Additionally, from a business perspective, matte lamination is preferred by most businesses since it conveys a more serious and authoritative tone in finished products.

- Anti-scrath gloss/matte lamination

Unlike standard gloss/matte lamination, this one is both optically flawless and resistant to scratches thanks to innovative lamination technology. In order to avoid scratches and wear, it is best used on large sections of solid-colored card surfaces (such as black and red).

- Silk matte lamination

It's a high-quality finish that's neither completely glossy nor completely matte, giving you the best of both worlds in terms of feel and functionality. The use of spot UV in combination with this technique can provide striking visual effects.

- Common gloss varnish

This imported gloss effect follows industry standards. Colors are boosted while regular dirt and water resistance are maintained. Normal playing cards and flashcards typically utilize this. It's possible that the gloss might cause a color loss on PVC cardstock, though.

- UV gloss/matte varnish

Most people go for this one. Ultraviolet (UV) radiation is used to speed up the curing and drying processes, resulting in a coating with an extremely high gloss. Compared to the aforementioned techniques, it offers the greatest gloss (particularly for dark colors), more abrasion resistance, and greater clarity. Additionally, it is a material that is good for the environment and can be recycled.

Another option is our UV matte varnish, which is somewhat more reflective than standard matte varnish.

- Glossy varnish Casino standard

Specifically, it's a coating used for playing cards in casinos. The special, pliable covering makes the cards easier to handle, more comfortable to shuffle, and less likely to snag. Its durability is particularly outstanding, making it ideal for the rough and tumble of casino gaming tables the world over.

- Butter varnish Cardistry standard

It's a high-end coating that looks great. The semi-matte varnishing finish is ideal for cardistry decks, magic decks, and other uses where a high degree of visual stealth is required. In addition, it ensures a sophisticated look while providing unmatched smoothness, touch, shuffle, and cutting.

Lamination vs Varnish

The term "lamination" refers to the process of applying an adhesive coating on the outside of a card or box. Gloss lamination and matte lamination are the two primary effects.

Prints can be varnished either while they are still in the printing process or later. However, varnish finishing is often less glossy than the aforementioned lamination.

Special Finish For Cards

- Hot stamping (one side or both sides)

Hot stamping also referred to as foil stamping, is a type of relief printing. Stamping in cards and packaging serves primarily a decorative function by transferring colored aluminum foil into the surface by heat pressing, resulting in a unique metallic hue. Request a catalog to see the wide variety of laser engraving patterns and metal stamping colors we provide.

What is the process of hot stamping? The hot foil stamping machine, the most important piece of machinery in the hot foil stamped process, must be controlled by hand by a skilled worker. Because we use the same equipment for both foil stamping and embossing (or debossing), you may combine the two processes for an even more impressive end result.

- Holographic lamination (one side or both sides)

A premium lamination service, it offers a variety of designs at a somewhat high cost. The holographic effect is glossy and modern, giving the design a sense of high-end sophistication. When used properly, it can prevent the card or box from warping, delaminating, fading, and even moisture damage. This, however, disrupts the fluidity of any cutting or shuffling action. The minimum order quantity is 250 decks.

- Spot UV (one side or both sides)

You may think of spot UV as an alternative to UV varnish in terms of its impact. Spot UV printing technique technology is a great way to highlight specific elements without making the entire card or box face overly flashy.

- Hot gilt edging

Depending on the technique used to create it, there are two distinct categories of edging:

1. Gilt edging, including edges made of gold, silver, black, pink, and other colors.

2. Cold matte edging.

Edging, in a similar vein, serves as a sort of edge embellishment for the card, elevating the overall quality of the product. Both hot and cold processes are included in the variety of methods. The different techniques can be divided into heat treatment and cold treatment. Among them, heat treatment is suitable for cards after the oil treatment (varnish), while cold treatment is suitable for cards after glue treatment (lamination).

Our popular colors are gold, silver, and holographic. For other colors, please ask us.

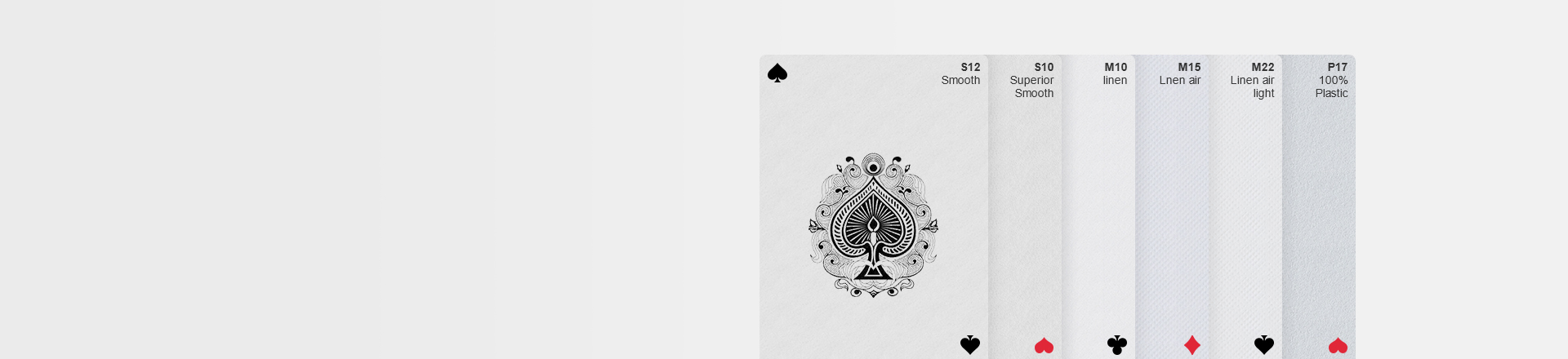

- Linen Effect Imprinting (both sides)

Exquisite playing cards and gaming cards frequently include a linen texture as a unique finish. In the "Cardstock" section, we detail its qualities.

Linen-textured cardstock is one of the possibilities we offer, although its tactile feel and lines may be diminished by printing and other surface treatments. Choose a smooth cardstock for crisper lines and touches, and then finish it with a linen texture if you like.

After printing is complete, post-processing work is required to add linen textures. To make the crosshatch design, the paper will be crushed under a large metal roller with the pattern, which will cause the lines to be etched into the paper.

Common Finish For Boxes

The box's common finishes match the card's, and you may go back to the previous paragraphs for further information about it, such as:

- Common glossy lamination

- Common gloss varnish

- Common matte lamination

- Common matte varnish

- Anti-scratch gloss lamination

- Anti-scratch matte lamination

- Silk matte lamination

Special Finish For Boxes

- Emboss vs Deboss

Creating a convex or concave surface on a box can be accomplished by embossing or debossing, respectively, using a mold or metal plate. It can emphasize the local design and turn 2D into 3D in terms of visual and tactile sensation.

Names and logos are commonly embossed, whereas borders, underlines, background patterns, etc. are often debossed.

In addition, specialized processes like hot stamping are frequently used in tandem with embossing and debossing.

You can refer back to the preceding paragraphs for detailed descriptions of the following optional special finishes for the box, which are analogous to those for the card:

- Hot stamping

- Linen Effect Imprinting

- Holographic lamination

- Spot UV

Common Finish For Booklets

The common finish of the booklet is similar to that of the card, and you can return to the top to see the relevant descriptions, including:

- Common glossy lamination

- Common glossy varnish

- Common matte lamination

- Anti-scratch matte lamination

- Silk matte lamination

Special Finish For Booklets

- Hot stamping single side

- Spot UV single side

Conflict Processes

In the process of finishing, some finishes are not able to be used together, otherwise it is easy to cause color loss, inaccurate registration, unclear printing and other problems. Specific conflict processes are listed below:

|

All lamination |

X |

Hot gilt edging |

|

All lamination |

X |

Linen effect |

|

All varnish |

X |

Cold gilt edging |

|

All gloss lamination |

X |

Spot UV |

|

All gloss varnish |

X |

Spot UV |

|

Hot stamping |

X |

Linen effect |

Relevant

- Design Guide

- Brief Introduction To Acelion's Designer

- How To Fast Design A Deck Of Cards?

- How To Set The Canvas?

- How To Add/Edit Text?

- How To Edit The Images?

- How To Upload Local Images?

- How To Set The Background Of The Card?

- How To Design Special Finishes?

- How To Use Masks For Playing Cards?

- How To Use The Downloaded Template Files?

- Printing Guide

- Brief Introduction To Acelion's Printing

- How To Choose Your Cardstock?

- How To Select Your Finish?

- How To Upload Your Files?

- How The Press Runs?

- What Is Our Quality Control?

- Order Support

- After Sales Service Policy

- FAQ

- FAQ