Printer Compatibility: Laser, Inkjet Or Offset For Playing Cards Printing?

Whether you're a professional playing card manufacturer or an enthusiast looking to print custom decks at home, choosing the right printer and understanding the different printing processes is crucial.

Playing cards require precise color reproduction, sharp imagery, and durable materials to withstand frequent shuffling and handling. In this comprehensive guide, we'll explore the compatibility of various printers with playing card printing, their respective processes, advantages, and disadvantages.

Different Ways For Playing Cards Printing

Laser Printer

Laser printers are a popular choice for printing playing cards due to their high-resolution output and ability to produce sharp, crisp images. The process involves using toner, a dry powder material, which is transferred onto the paper through electrostatic charges and fused with heat, resulting in a durable and smudge-resistant print.

Advantages:

- High-resolution output: Laser printers can produce images with resolutions up to 1200 dpi or higher, ensuring precise and detailed card designs.

- Fast printing speed: Laser printers are generally faster than inkjet printers, making them suitable for larger print runs.

- Durable prints: The toner used in laser printing is resistant to water, fading, and smudging, ensuring long-lasting card quality.

Disadvantages:

- Limited color gamut: Laser printers typically have a smaller color gamut compared to inkjet printers, which can result in less vibrant and accurate color reproduction.

- Costly consumables: Toner cartridges for laser printers can be expensive, especially for high-volume printing.

- Limited paper handling: Some laser printers may have limitations in handling thicker or specialty paper stocks commonly used for playing cards.

- Printing ink loss: When printing on a laser printer, the toner does not bond well to the card stock, often only bonding well to one side of the card.

Inkjet Printer (The Most Used Digital Way For Playing Cards Printing)

Inkjet printers use liquid ink cartridges to produce high-quality prints on a wide range of materials, including card stocks suitable for playing cards. The printing process involves spraying microscopic droplets of ink onto the paper, resulting in vibrant and detailed images. For orders below 200 decks, we default to using inkjet printer (HP digital printer) to provide you with more affordable prices.

Advantages:

- Wide color gamut: Inkjet printers can reproduce a broader range of colors than a Laser printer, providing more accurate and vivid color reproduction for playing card designs.

- Versatile media handling: Many inkjet printers can handle a variety of paper types and thicknesses, making them suitable for printing on specialized card stocks.

- Cost-effective for small runs: Inkjet printers are generally more affordable than laser printers, making them a cost-effective option for printing small quantities of custom playing cards.

Disadvantages:

- Slower print speed: Inkjet printers tend to have slower print speeds compared to laser printers, which can be a limitation for larger print runs.

- Limited durability: Inkjet prints are susceptible to smudging, fading, and water damage, which can affect the longevity of playing cards.

- Potential for ink bleeding: Depending on the paper stock and ink quality, ink bleeding or feathering can occur, compromising the sharpness and clarity of playing card designs. Also, the color fineness is poor compared to offset printers.

Offset Printer

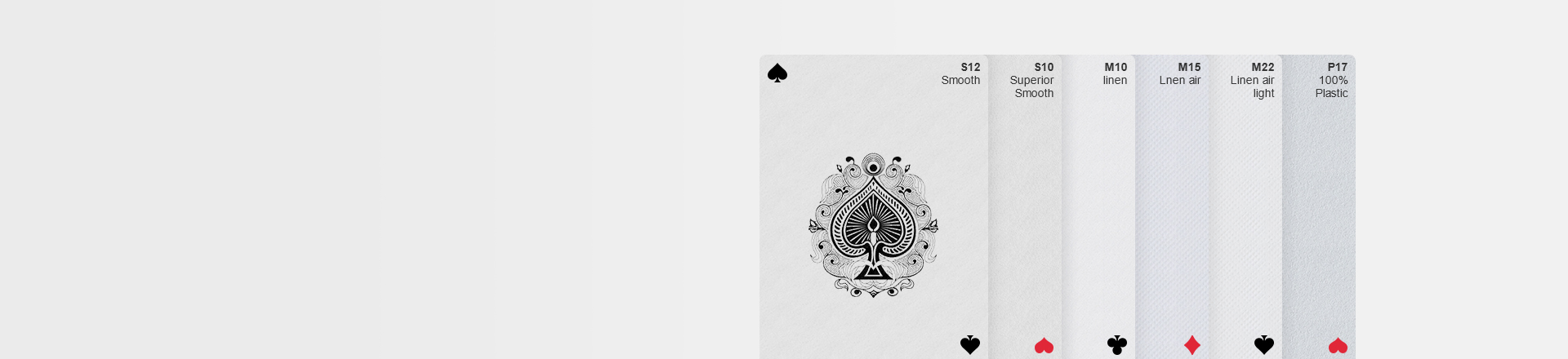

Offset printing is a professional printing method widely used in the commercial production of playing cards. It involves transferring ink from a plate to a rubber blanket and then onto the paper, resulting in high-quality and consistent prints. For orders of are or more than 200 decks, we use an offset printer (Heidelberg press) by default to provide excellent printing quality and a lower unit price.

Advantages:

- Exceptional print quality: Offset printing produces sharp, vibrant, and consistent prints with precise color reproduction, making it ideal for playing card manufacturing.

- Cost-effective for large runs: While offset printing has higher setup costs, it becomes more cost-effective for large print runs due to economies of scale.

- Versatile media handling: Offset presses can handle a wide range of paper stocks, including specialized card stocks used for playing cards.

Disadvantages:

- High setup costs: Offset printing requires expensive equipment and specialized plates, which can be cost-prohibitive for small print runs.

- Limited customization: Offset printing is best suited for larger print runs with consistent designs, as setup costs make frequent design changes impractical.

- Longer turnaround times: The offset printing process involves several steps, including plate-making and press setup, which can result in longer turnaround times compared to digital printing methods.

Acelion Playingcards: Personalized Card Products Made Easy

Acelion Playingcards is a renowned provider of custom playing card solutions, offering automated quotation, design, and POD services to customers worldwide. Our streamlined process allows you to create personalized card products at competitive prices, whether you need a single deck or 10,000 decks.

With Acelion Playingcards, you can:

1. Automated Quotation: Receive instant quotes based on your desired quantity, card stock, and printing specifications, enabling you to make informed decisions.

2. Intuitive design service: Easily transform your artistic designs into printable, professional files with our designer specifically built for card printing.

3. Print-on-Demand (POD): Take advantage of our POD capabilities, which enable efficient and cost-effective production of custom playing cards in any quantity.

4. Competitive Pricing: Benefit from our scale and streamlined processes, ensuring competitive pricing without compromising on quality.

5. Quality Assurance: Rest assured that your playing cards will meet the highest standards of print quality, durability, and longevity, thanks to their rigorous quality control measures.

How To Choose The Right Printer To Make Playing Cards?

When choosing the right printer for making playing cards, consider the following factors:

- Print volume: Determine the number of decks you plan to print. For small quantities, inkjet or laser printers may be suitable, while offset printing is more cost-effective for large volumes.

- Print quality requirements: Evaluate the level of detail, color accuracy, and sharpness required for your playing card designs. Offset and high-end laser printers generally offer superior print quality.

- Paper stock compatibility: Ensure that the printer can handle the thickness and material of the card stock you plan to use for your playing cards.

- Cost considerations: Factor in the initial printer cost, consumables (ink/toner), and maintenance costs over the long term.

- Turnaround time: If you have tight deadlines, consider printers with faster print speeds or seek professional printing services for larger runs.

If you're looking to produce custom playing cards in smaller quantities or with frequent design changes, Acelion's POD services may be the ideal solution. Our automated processes and professional designer can help you bring your playing card visions to life with ease and efficiency.

Summary

Printing playing cards requires careful consideration of the printer technology, print quality, cost, and compatibility with specialized card stocks.

Whether you opt for laser, inkjet, or offset printing, or leverage the services of Acelion Playingcards, the key is to understand your requirements and choose the solution that best meets your needs.

Relevant

- Blog

- Creative Ideas for Artist Trading Cards: 30 Unique Inspirations

- Specialty Paper Guide: 4 Powerful & Stunning Types That Impress

- Top 20 Modern Card Deck Ideas To Strong Custom Printing

- Online Card Maker: 5 Powerful Free vs Paid Features to Save Big

- 20 Creative Board Game Ideas to Spark Fun & Learning

- 5 Environmentally Friendly Game Card Packaging Solutions

- A History of the Tarot: From Card Game to Cosmic Symbolism

- Creative Playing Cards: 5 Bold Design Inspirations

- How Custom Corporate Cards Enhance Branding and How They Are Made

- Why And How To Design Your Own Flashcards?

- The Magnetic Charm of Cardistry: A Modern Art Form's Enduring Appeal

- 290gsm Italian Black Core Vs 300gsm Japan Black Core: A Deep Dive into Premium Playing Card Materials

- The Art Of Shine: A Complete Guide To Foil Printing In Playing Card Design

- Remembering Complex Tarot Spreads With Custom Instruction Booklets

- Packaging For Your Playing Card Box: Shrink Wrap vs. Cello Wrap

- Modern Innovations In Playing Card Design: A New Era Of Creativity And Functionality

- The Spade Symbol: The Origins And Inspirations Behind Playing Card Design 1

- The Ultimate Color Psychology Guide to Print Promotional Playing Cards 2

- Choosing the Best Online Playing Card Printer

- 10 Innovative Tips For Crafting Effective Marketing Playing Cards

- Use Canva To Create Print-Ready Playing Card Files

- Online Card Printing Checklists: Mastering Print Perfection

- Advertising Playing Cards Myths: Use Them To Maximize Your Business Growth

- How To Choose An Online Custom Playing Card Website 1?

- The Booming World Of Custom Card Game Market

- Waterproof Elements: A Dive into Plastic Playing Cards

- How to Customize Playing Cards: Interview From The Card Designer

- Playing Card Deck Printing for Prototypes and Limited Editions

- Playing Card Size: Design Overview And Guide

- Dealing Up Fun: A Guide to Card Games for Kids

- Dealing Up Fun: A Guide to Card Games for Adults

- How To Make Playing Cards #3: Specifications To Print Playing Cards

- How To Make Playing Cards #2: Elements About Designing Playing Cards

- How To Make Playing Cards #1: Techniques To Design Playing Cards

- Coolest Playing Card Designs That Cut a Figure In 2024

- How To Design For Tarot Brands And Astrology Tarot Cards

- Tarot Color Symbols: 12 Important Colors In Tarot Cards

- Card Game Design: 4 Playing Card Design Ideas

- The Hidden Worlds: A Journey Through Tarot Card Back Designs

- A Shuffle Through 2024: Popular Playing Card Designs

- How To Design And Make a Window Tuck Box For Playing Cards?

- Playing Cards Drawing Ideas And Design Inspiration

- From Paper To Plastic: What Are Playing Cards Made Of?

- How To Make Flashcards: A Comprehensive Guide For Effective Flashcards

- How To Make Tarot Cards Out Of Playing Cards?

- Create Any Design And Make Playing Cards At Acelion Playingcards

- How To Play Poker For Beginners 1: Hearts And Spades Card Game

- How To Play Poker For Beginners 2: Speed And War Card Game

- Designs Of Playing Card Suits: A Dive Into The Markings Of A Deck

- Color Psychology in Playing Card Design: Beyond Red and Black

- Number Typography and Readability For Playing Cards Design

- 10 Card Game Design Blogs And Websites To Explore

- Understanding Tarot Card Designs: Core Principles and Significance

- Card Deck Design: Customization and Personalization

- Custom Playing Cards: Regional Variations In Playing Card Design

- Finding Your Ideal Tarot Card Manufacturer: A Step-by-Step Guide

- POD Compliance and Legal Considerations For Trading Card Game

- April Fool's Day and the Fool Tarot Card: A Curious Juxtaposition

- Face Cards Evolution 1: The Design Journey of Playing Card Courts

- Face Cards Evolution 2: The Design Journey of Playing Card Courts

- Hierarchy Of Poker: A Guide To Poker Hand Rankings

- Printing Services vs. DIY Printing: The Great Debate For Custom Playing Cards

- Printer Compatibility: Laser, Inkjet Or Offset For Playing Cards Printing?

- Playing Card Packaging Options: Protect and Present Your Decks in Style

- Tarot Printing: Choosing High-Quality Images

- The Role of Technology in Creating Custom Game Cards

- How To Choose An Online Custom Playing Card Website 2?

- Creative And Fun Uses For Trading Cards: Beyond The Basics

- Why And How To Fully Custom Game Cards Both Sides?

- Why And How To Fully Custom Game Cards Both Sides?

- Playing Card Printing: Equipment, Setup, and Troubleshooting

- The Ultimate Guide To Black Core Cardstock: Durability, Options, And Iconic Decks

- The Ins and Outs of Custom Playing Card Materials and Finishes

- 5 Money-Saving Tips (With Custom Cards) For Small Businesses

- The Art of Special Finishes: Elevating Custom Cards with Unique Touches

- 6 Essential Considerations When Selecting the Ideal Online Card Printer

- Copyright Guidelines for Game Card Designers

- Discover The Advantages Of Printing Cards With AcelionPlayingCards.Com

- Why You Need to Choose a Good Font for Your Game Cards

- The Ultimate Color Psychology Guide to Print Promotional Playing Cards 1

- 10 Essential Factors To Consider When Designing High-Quality Playing Cards

- Mastering Spades Playing Cards: The Most Popular Questions Answered

- How Many Cards Should You Design For Custom Card Decks?

- The Best Teacher Gifts for Anytime of Year: Flash Cards and Board Games

- Playing Cards: Icons Of Pop Culture And Their Fascinating Journey

- The 5 Benefits of Playing with Custom Game Cards

- Educational Benefits of Custom Memory Game Cards: Enhancing Cognitive Development Across Age Groups

- Debunking 6 Tarot Card Myths And Beginner Tips For Tapping Into Your Intuition

- Print-Ready Tarot File: Enlarge the Image

- Top 7 Most Discussed Topics By Playing Card Creators

- 5 Steps To Craft A Hit Card Game

- Managing Dies for Card Printing Precision: A Masterclass in Craftsmanship

- The Timeless Deck: Rediscovering the Relevance of Paper Playing Cards in the Digital Age

- The Spade Symbol: Unraveling the Origins and Inspirations Behind Playing Card Design 2

- Cardstock Options For Custom Playing Cards: An Order Guide

- The Uses of Playing Cards: A Journey Through History and Versatility

- How To Solve Difficulty In Shuffling With The Right Playing Cardstock And Finishes?

- Acelion Playing Card's Environmental Commitment: For a Greener Tomorrow

- Why Choose China For Custom Card Printing From Acelion’s Insights

- Use Jumbo Playing Cards To Solve Difficulty In Playing With Large Groups

- What Caused The Explosion In Custom Tarot Decks?

- Design Wedding Playing Cards as Unique Guest Gifts with POD Services

- 10 Creative Playing Card Inspirations That Will Blow Your Mind

- Effortless Custom Corporate Playing Cards: 1 Design & Production Guide

- Wedding Playing Cards: 54 Romantic Ways to Tell Your Love Story

- Wedding Poker Cards: 10 Stunning Theme Design Ideas

- Custom Corporate Playing Cards: Amazing Boost in 2025

- Wedding Poker: Unlock 5 Powerful Customization Trends

- Custom Corporate Poker: 7 Stunning Ideas to Amplify Branding

- Online Card Maker: 5 Powerful Ways to Boost Holiday Sales

- Online Card Maker Trends 2025: Bold AI & AR Innovations

- Creative Poker Ideas: 5 Stunning, Happy Custom Gift Decks

- Custom Playing Cards: 5 Successful Industries That Thrive

- DIY Game Cards: 5 Exciting Ways Online Tools Transform Creativity

- Custom Poker Cards: 5 Powerful Ways to Boost ROI & Brand Love

- Custom Wedding Playing Cards: 10 Fun, Engaging Games for Epic Joy

- 20 Creative Wedding Favor Ideas Your Guests Will Love

- 18 Creative Corporate Promotion Ideas to Boost Your Brand

- Meeting Minimum Order Quantities: A Solution for Independent Artists and Small Businesses

- How to Publish Your First Tarot Deck: A Step-by-Step Guide for Creators

- How to Manage Your Game Card Printing Design: A Comprehensive Guide

- 5 Tarot Books You Should Read In 2025

- Cardstock Options For Custom Playing Cards: An Order Guide

- The Art Of Deception: The Magic Of Playing Cards In Cinema

- POD Playing Cards Trends in 2025: Print & Design Insights

- Why Is Playing Cards Important?

- 7 Experiences in Designing Game Cards: A Game Designer’s Journey

- 10 Unique Oracle Decks You Can Create for Spiritual Growth and Inspiration

- The Magic of Customization: Why Personalized Game Cards Outshine the Rest

- Card Game Accessibility and Customization: Making Games Welcoming and Personal

- 10 Ways Publishers Can Support Their Playing Card Decks

- The Cost of Playing Card Printing: Why Metallic Stamping Is So Expansive?

- Narrative Game Card Design: Weaving Stories Through Cards

- Engaging Flashcard Designs: Fun Ideas and Customizable Templates

- Science-Based Flashcard Design: Proven Techniques for Maximum Retention and Learning

- 15 Creative Uno Customizable Cards Ideas for Fun Gameplay

- Custom Quote Cards: 5 Stunning Ways to Inspire Your Next Project

- Custom Quote Card Ideas: 10 Creative Designs for Any Occasion

- Make the Playing Cards Near Me in USA: 10 Best Picks You’ll Love!

- 20 Inspirational Quotes for Printable Quotes Cards

- DIY Playing Cards: 52 Bold Ways to Tell Epic Brand Stories

- Make the Playing Cards Near Me UK – 10 Powerful Options Reviewed

- Positive Quotes Card Printing: 15 Strong Inspires with Custom Designs

- Life Quotes Card Printing: 20 Inspiring Designs to Elevate Joy

- Success Quotes Card Printing: 7 Inspiring Designs to Empower You

- Ace of Spades Card: 5 Powerful Reasons It Still Dominates

- How to Play Dominoes: 7 Brilliant Tips to Instantly Win More Games

- Quote Of The Day For Work Card Printing: 10 Powerful Ideas

- Playing Cards on Demand: 7 Powerful Reasons Creators Love Acelion

- Cute Quotes Card Printing: 12 Powerful Phrases to Boost Sales

- Fathers Day Card Idea: 20 Powerful & Heartwarming Designs

- Mothers Day Card Ideas: 20 Heartfelt & Powerful Gift Picks

- Aesthetic Quotes: 12 Stunning Ideas for Powerful Card Printing

- Print on Demand Tarot Cards: 7 Powerful Reasons to Start from Acelion

- Birthday Card Ideas: 13 Brilliant Ways to Create Unforgettable Joy

- 15 Valentines Day Card Ideas That Truly Wow & Inspire

- Make the Playing Cards Near Me in Japan: 10 Best Powerful Picks

- Online Card Maker: 7 Powerful Tips to Avoid Costly Mistakes

- Online Card Maker: 7 Powerful Benefits for Small Biz Success

- Creative Playing Cards: 7 Powerful Reasons Collectors Love Them

- Personalized Deck of Cards: 10 Powerful Reasons to Love It

- Eco Card Printing: 7 Powerful Reasons to Go Gree

- Gloss vs Matte: 7 Powerful Reasons to Choose the Right Finish

- POD Playing Cards: 5 Powerful Answers to Avoid Costly Mistakes

- Symbolism of Cardology: 10 Powerful Secrets You Should Know

- Customize Luxurious Playing Cards: 6 Powerful Reasons Why You Should Try

- Custom Card Games: 10 Powerful Ways for Positive Success

- Thank You Card Ideas: 5 Powerful Creative Tips That Inspire

- Poker Anti-Counterfeiting: 5 Powerful Ways to Avoid Fake Cards

- Sustainable Game Cards: 7 Powerful Benefits You Should Know

- Custom TCG: 8 Powerful Reasons for Massive Success

- Playing Card Back Design: 6 Powerful Tips for Stunning Success

- Trading Card Copyright: 8 Shocking Risks & Powerful Tips

- Creative Poker Gameplay: 7 Exciting Powerful Ideas