Managing Dies for Card Printing Precision: A Masterclass in Craftsmanship

When you hold a deck of cards, what you’re really holding is the result of an intricate dance between precision engineering, creativity, and craftsmanship. Each card’s clean edges, rounded corners, and tactile elegance owe their existence to one critical element: die management.

From conceptualizing shapes to maintaining micrometer-level accuracy, managing dies is an unsung yet indispensable art. This article dives deep into the meticulous printing process of die management, enriched with fresh perspectives, examples, and insights.

The Foundation: Die Inventory Management

Imagine a well-organized library where each book is cataloged down to its last detail. That’s what Acelion’s "Die Inventory System" represents. It’s a centralized excel that catalogs every die we own, whether it’s for classic rectangular cards or bespoke designs for limited editions. This file not only tracks physical dies but also their specifications, material types, and usage history.

Consider a scenario where a client requests a one-of-a-kind hexagonal card design for a promotional campaign. Without an up-to-date inventory, locating or creating the required die could delay production. By maintaining meticulous records, we can quickly identify whether we already have a suitable die or if a new one needs to be fabricated, significantly reducing lead times and ensuring smooth operations.

Microscopic Precision: The Role of Quality Control

In the realm of die management, quality control is not optional; it’s a necessity. A misaligned or dull die can wreak havoc, leading to jagged edges or inconsistent cuts that compromise the final product. Regular inspections and maintenance are vital to upholding the highest standards.

For instance, embossing dies used for premium playing cards demand flawless sharpness to imprint intricate designs. We employ advanced measuring tools such as digital micrometers and optical comparators to ensure every die meets our stringent criteria. Any anomaly—even one invisible to the naked eye—is promptly rectified.

Case Study: When we noticed a decline in the output quality of our gold-foil stamped cards, a detailed inspection revealed micro-wear on the die’s edges. A quick refurbishment restored its precision, averting a potential production bottleneck.

Elevating Comfort: The Round Corner Revolution

Gone are the days of sharp-edged cards that left your fingers nicked. Rounded corners not only enhance comfort but also increase durability by reducing wear and tear. Achieving this requires specialized corner-rounding dies designed for precision and efficiency.

Take playing cards, for example. These are shuffled, dealt, and handled repeatedly, making them susceptible to damage. By using advanced corner-rounding dies, we produce cards that retain their shape and aesthetic even after prolonged use. This seemingly minor detail significantly extends the product’s lifespan and elevates user satisfaction.

Fun Fact: Rounded corners are now a benchmark for premium cards across industries, from gaming to business cards, thanks to their ergonomic and aesthetic advantages.

Beyond Basics: Special Effects with Dies

Dies are not just cutting tools; they are gateways to creativity. With the right die, we can emboss, deboss, and even add textures that transform an ordinary card into a tactile masterpiece. Special effects like foil stamping and spot UV coating are achieved through precision-engineered dies, adding a layer of sophistication and exclusivity.

For example, imagine a collector’s edition trading card with an intricate embossed dragon, its scales highlighted by gold foil. This level of craftsmanship is possible because of meticulously designed dies that align perfectly with the artwork.

Innovation in Action: Recently, we introduced a dual-layered die system to create cards with multi-dimensional textures, allowing clients to add depth and uniqueness to their designs.

Cost and Efficiency: Striking the Perfect Balance

Dies are a significant investment, with costs ranging from hundreds to thousands of dollars. Effective management requires a delicate balance between maintaining quality and optimizing costs. By analyzing usage patterns and production schedules, we ensure that each die is utilized to its fullest potential without compromising performance.

For instance, we monitor the wear-and-tear metrics of frequently used dies, scheduling maintenance or replacements at optimal intervals. This proactive approach minimizes downtime and maximizes cost-efficiency.

Savings Insight: Implementing a predictive maintenance program reduced our die replacement costs by 20% last year, while also improving production uptime by 15%.

Passing the Torch: Training for Excellence

Die management is as much about people as it is about tools. We invest heavily in training programs to ensure our operators are skilled in handling and maintaining dies. From proper storage techniques to advanced troubleshooting, these sessions empower our team to uphold our high standards.

Example: During a recent onboarding session, we demonstrated the correct method for cleaning foil-stamping dies. This seemingly minor detail prevents residue buildup, which can compromise quality over time. New hires also learn to use digital tools to monitor die performance, fostering a culture of precision and accountability.

Conclusion: Precision as an Art Form

Managing dies for card printing precision is a blend of science, engineering, and artistry. From maintaining an exhaustive inventory to embracing cutting-edge technologies like laser-cutting, every step reflects our commitment to excellence. This meticulous process ensures that every card we produce—whether a standard playing card or a luxurious collector’s item—is nothing short of perfection.

So, the next time you shuffle a deck or marvel at the intricate details of a premium card, remember the dedication and expertise that went into creating it. At the heart of it all lies the quiet yet crucial art of die management—an unsung hero of card production. Let’s craft something extraordinary together!

Relevant

- Blog

- Creative Ideas for Artist Trading Cards: 30 Unique Inspirations

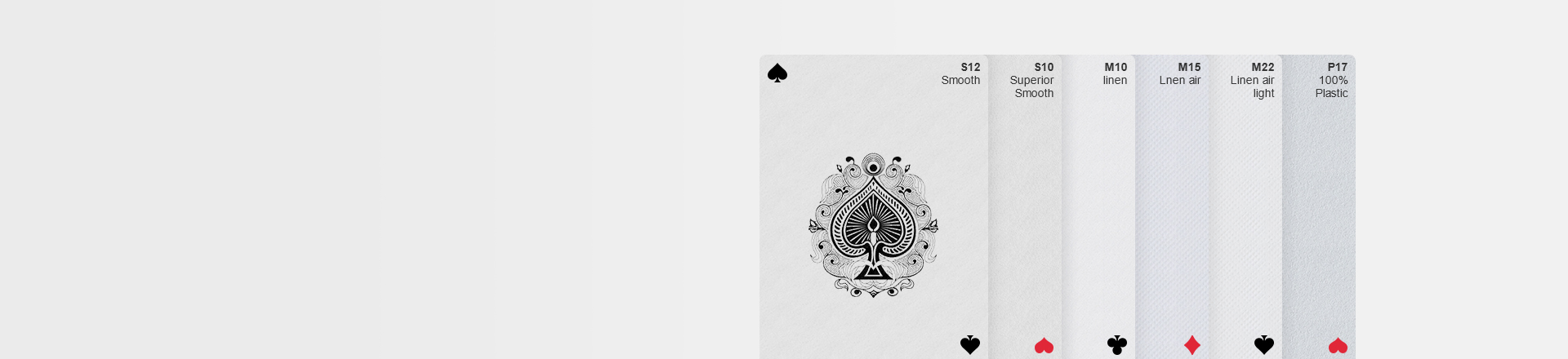

- Specialty Paper Guide: 4 Powerful & Stunning Types That Impress

- Top 20 Modern Card Deck Ideas To Strong Custom Printing

- Online Card Maker: 5 Powerful Free vs Paid Features to Save Big

- 20 Creative Board Game Ideas to Spark Fun & Learning

- 5 Environmentally Friendly Game Card Packaging Solutions

- A History of the Tarot: From Card Game to Cosmic Symbolism

- Creative Playing Cards: 5 Bold Design Inspirations

- How Custom Corporate Cards Enhance Branding and How They Are Made

- Why And How To Design Your Own Flashcards?

- The Magnetic Charm of Cardistry: A Modern Art Form's Enduring Appeal

- 290gsm Italian Black Core Vs 300gsm Japan Black Core: A Deep Dive into Premium Playing Card Materials

- The Art Of Shine: A Complete Guide To Foil Printing In Playing Card Design

- Remembering Complex Tarot Spreads With Custom Instruction Booklets

- Packaging For Your Playing Card Box: Shrink Wrap vs. Cello Wrap

- Modern Innovations In Playing Card Design: A New Era Of Creativity And Functionality

- The Spade Symbol: The Origins And Inspirations Behind Playing Card Design 1

- The Ultimate Color Psychology Guide to Print Promotional Playing Cards 2

- Choosing the Best Online Playing Card Printer

- 10 Innovative Tips For Crafting Effective Marketing Playing Cards

- Use Canva To Create Print-Ready Playing Card Files

- Online Card Printing Checklists: Mastering Print Perfection

- Advertising Playing Cards Myths: Use Them To Maximize Your Business Growth

- How To Choose An Online Custom Playing Card Website 1?

- The Booming World Of Custom Card Game Market

- Waterproof Elements: A Dive into Plastic Playing Cards

- How to Customize Playing Cards: Interview From The Card Designer

- Playing Card Deck Printing for Prototypes and Limited Editions

- Playing Card Size: Design Overview And Guide

- Dealing Up Fun: A Guide to Card Games for Kids

- Dealing Up Fun: A Guide to Card Games for Adults

- How To Make Playing Cards #3: Specifications To Print Playing Cards

- How To Make Playing Cards #2: Elements About Designing Playing Cards

- How To Make Playing Cards #1: Techniques To Design Playing Cards

- Coolest Playing Card Designs That Cut a Figure In 2024

- How To Design For Tarot Brands And Astrology Tarot Cards

- Tarot Color Symbols: 12 Important Colors In Tarot Cards

- Card Game Design: 4 Playing Card Design Ideas

- The Hidden Worlds: A Journey Through Tarot Card Back Designs

- A Shuffle Through 2024: Popular Playing Card Designs

- How To Design And Make a Window Tuck Box For Playing Cards?

- Playing Cards Drawing Ideas And Design Inspiration

- From Paper To Plastic: What Are Playing Cards Made Of?

- How To Make Flashcards: A Comprehensive Guide For Effective Flashcards

- How To Make Tarot Cards Out Of Playing Cards?

- Create Any Design And Make Playing Cards At Acelion Playingcards

- How To Play Poker For Beginners 1: Hearts And Spades Card Game

- How To Play Poker For Beginners 2: Speed And War Card Game

- Designs Of Playing Card Suits: A Dive Into The Markings Of A Deck

- Color Psychology in Playing Card Design: Beyond Red and Black

- Number Typography and Readability For Playing Cards Design

- 10 Card Game Design Blogs And Websites To Explore

- Understanding Tarot Card Designs: Core Principles and Significance

- Card Deck Design: Customization and Personalization

- Custom Playing Cards: Regional Variations In Playing Card Design

- Finding Your Ideal Tarot Card Manufacturer: A Step-by-Step Guide

- POD Compliance and Legal Considerations For Trading Card Game

- April Fool's Day and the Fool Tarot Card: A Curious Juxtaposition

- Face Cards Evolution 1: The Design Journey of Playing Card Courts

- Face Cards Evolution 2: The Design Journey of Playing Card Courts

- Hierarchy Of Poker: A Guide To Poker Hand Rankings

- Printing Services vs. DIY Printing: The Great Debate For Custom Playing Cards

- Printer Compatibility: Laser, Inkjet Or Offset For Playing Cards Printing?

- Playing Card Packaging Options: Protect and Present Your Decks in Style

- Tarot Printing: Choosing High-Quality Images

- The Role of Technology in Creating Custom Game Cards

- How To Choose An Online Custom Playing Card Website 2?

- Creative And Fun Uses For Trading Cards: Beyond The Basics

- Why And How To Fully Custom Game Cards Both Sides?

- Why And How To Fully Custom Game Cards Both Sides?

- Playing Card Printing: Equipment, Setup, and Troubleshooting

- The Ultimate Guide To Black Core Cardstock: Durability, Options, And Iconic Decks

- The Ins and Outs of Custom Playing Card Materials and Finishes

- 5 Money-Saving Tips (With Custom Cards) For Small Businesses

- The Art of Special Finishes: Elevating Custom Cards with Unique Touches

- 6 Essential Considerations When Selecting the Ideal Online Card Printer

- Copyright Guidelines for Game Card Designers

- Discover The Advantages Of Printing Cards With AcelionPlayingCards.Com

- Why You Need to Choose a Good Font for Your Game Cards

- The Ultimate Color Psychology Guide to Print Promotional Playing Cards 1

- 10 Essential Factors To Consider When Designing High-Quality Playing Cards

- Mastering Spades Playing Cards: The Most Popular Questions Answered

- How Many Cards Should You Design For Custom Card Decks?

- The Best Teacher Gifts for Anytime of Year: Flash Cards and Board Games

- Playing Cards: Icons Of Pop Culture And Their Fascinating Journey

- The 5 Benefits of Playing with Custom Game Cards

- Educational Benefits of Custom Memory Game Cards: Enhancing Cognitive Development Across Age Groups

- Debunking 6 Tarot Card Myths And Beginner Tips For Tapping Into Your Intuition

- Print-Ready Tarot File: Enlarge the Image

- Top 7 Most Discussed Topics By Playing Card Creators

- 5 Steps To Craft A Hit Card Game

- Managing Dies for Card Printing Precision: A Masterclass in Craftsmanship

- The Timeless Deck: Rediscovering the Relevance of Paper Playing Cards in the Digital Age

- The Spade Symbol: Unraveling the Origins and Inspirations Behind Playing Card Design 2

- Cardstock Options For Custom Playing Cards: An Order Guide

- The Uses of Playing Cards: A Journey Through History and Versatility

- How To Solve Difficulty In Shuffling With The Right Playing Cardstock And Finishes?

- Acelion Playing Card's Environmental Commitment: For a Greener Tomorrow

- Why Choose China For Custom Card Printing From Acelion’s Insights

- Use Jumbo Playing Cards To Solve Difficulty In Playing With Large Groups

- What Caused The Explosion In Custom Tarot Decks?

- Design Wedding Playing Cards as Unique Guest Gifts with POD Services

- 10 Creative Playing Card Inspirations That Will Blow Your Mind

- Effortless Custom Corporate Playing Cards: 1 Design & Production Guide

- Wedding Playing Cards: 54 Romantic Ways to Tell Your Love Story

- Wedding Poker Cards: 10 Stunning Theme Design Ideas

- Custom Corporate Playing Cards: Amazing Boost in 2025

- Wedding Poker: Unlock 5 Powerful Customization Trends

- Custom Corporate Poker: 7 Stunning Ideas to Amplify Branding

- Online Card Maker: 5 Powerful Ways to Boost Holiday Sales

- Online Card Maker Trends 2025: Bold AI & AR Innovations

- Creative Poker Ideas: 5 Stunning, Happy Custom Gift Decks

- Custom Playing Cards: 5 Successful Industries That Thrive

- DIY Game Cards: 5 Exciting Ways Online Tools Transform Creativity

- Custom Poker Cards: 5 Powerful Ways to Boost ROI & Brand Love

- Custom Wedding Playing Cards: 10 Fun, Engaging Games for Epic Joy

- 20 Creative Wedding Favor Ideas Your Guests Will Love

- 18 Creative Corporate Promotion Ideas to Boost Your Brand

- Meeting Minimum Order Quantities: A Solution for Independent Artists and Small Businesses

- How to Publish Your First Tarot Deck: A Step-by-Step Guide for Creators

- How to Manage Your Game Card Printing Design: A Comprehensive Guide

- 5 Tarot Books You Should Read In 2025

- Cardstock Options For Custom Playing Cards: An Order Guide

- The Art Of Deception: The Magic Of Playing Cards In Cinema

- POD Playing Cards Trends in 2025: Print & Design Insights

- Why Is Playing Cards Important?

- 7 Experiences in Designing Game Cards: A Game Designer’s Journey

- 10 Unique Oracle Decks You Can Create for Spiritual Growth and Inspiration

- The Magic of Customization: Why Personalized Game Cards Outshine the Rest

- Card Game Accessibility and Customization: Making Games Welcoming and Personal

- 10 Ways Publishers Can Support Their Playing Card Decks

- The Cost of Playing Card Printing: Why Metallic Stamping Is So Expansive?

- Narrative Game Card Design: Weaving Stories Through Cards

- Engaging Flashcard Designs: Fun Ideas and Customizable Templates

- Science-Based Flashcard Design: Proven Techniques for Maximum Retention and Learning

- 15 Creative Uno Customizable Cards Ideas for Fun Gameplay

- Custom Quote Cards: 5 Stunning Ways to Inspire Your Next Project

- Custom Quote Card Ideas: 10 Creative Designs for Any Occasion

- Make the Playing Cards Near Me in USA: 10 Best Picks You’ll Love!

- 20 Inspirational Quotes for Printable Quotes Cards

- DIY Playing Cards: 52 Bold Ways to Tell Epic Brand Stories

- Make the Playing Cards Near Me UK – 10 Powerful Options Reviewed

- Positive Quotes Card Printing: 15 Strong Inspires with Custom Designs

- Life Quotes Card Printing: 20 Inspiring Designs to Elevate Joy

- Success Quotes Card Printing: 7 Inspiring Designs to Empower You

- Ace of Spades Card: 5 Powerful Reasons It Still Dominates

- How to Play Dominoes: 7 Brilliant Tips to Instantly Win More Games

- Quote Of The Day For Work Card Printing: 10 Powerful Ideas

- Playing Cards on Demand: 7 Powerful Reasons Creators Love Acelion

- Cute Quotes Card Printing: 12 Powerful Phrases to Boost Sales

- Fathers Day Card Idea: 20 Powerful & Heartwarming Designs

- Mothers Day Card Ideas: 20 Heartfelt & Powerful Gift Picks

- Aesthetic Quotes: 12 Stunning Ideas for Powerful Card Printing

- Print on Demand Tarot Cards: 7 Powerful Reasons to Start from Acelion

- Birthday Card Ideas: 13 Brilliant Ways to Create Unforgettable Joy

- 15 Valentines Day Card Ideas That Truly Wow & Inspire

- Make the Playing Cards Near Me in Japan: 10 Best Powerful Picks

- Online Card Maker: 7 Powerful Tips to Avoid Costly Mistakes

- Online Card Maker: 7 Powerful Benefits for Small Biz Success

- Creative Playing Cards: 7 Powerful Reasons Collectors Love Them

- Personalized Deck of Cards: 10 Powerful Reasons to Love It

- Eco Card Printing: 7 Powerful Reasons to Go Gree

- Gloss vs Matte: 7 Powerful Reasons to Choose the Right Finish

- POD Playing Cards: 5 Powerful Answers to Avoid Costly Mistakes

- Symbolism of Cardology: 10 Powerful Secrets You Should Know

- Customize Luxurious Playing Cards: 6 Powerful Reasons Why You Should Try

- Custom Card Games: 10 Powerful Ways for Positive Success

- Thank You Card Ideas: 5 Powerful Creative Tips That Inspire

- Poker Anti-Counterfeiting: 5 Powerful Ways to Avoid Fake Cards

- Sustainable Game Cards: 7 Powerful Benefits You Should Know

- Custom TCG: 8 Powerful Reasons for Massive Success

- Playing Card Back Design: 6 Powerful Tips for Stunning Success

- Trading Card Copyright: 8 Shocking Risks & Powerful Tips

- Creative Poker Gameplay: 7 Exciting Powerful Ideas