Playing Card Printing: Equipment, Setup, and Troubleshooting

Playing cards, those ubiquitous companions for game nights and friendly wagers, have a surprisingly complex journey from design to your hand. While the basic concept seems straightforward, achieving high-quality, durable playing cards requires specialized equipment and a keen understanding of the printing process.

This article delves into the world of playing card printing equipment, exploring the advantages and disadvantages of different methods, setup and calibration techniques, quality control measures, and solutions for troubleshooting common printing issues.

The Big Guns: Industrial Playing Card Printing Equipment

Commercial playing card production relies on high-volume, high-precision industrial printing presses. Here, two primary methods dominate:

- Offset Lithography: This industry standard uses metal plates etched with the card design. Ink is transferred from the plates to a rubber blanket, then finally pressed onto the card stock. Offset printing offers exceptional detail, vibrant colors, and the ability to handle large print runs efficiently. However, the initial setup costs for creating the printing plates can be high, making it less suitable for small-scale projects. This is our main printing method.

- Web Presses: Designed for even faster production, web presses utilize continuous rolls of card stock instead of individual sheets. This method excels at churning out vast quantities of cards quickly, but the initial investment for web presses is even steeper than offset lithography. Additionally, web presses often require more specialized skills to operate.

Advantages:

- High-Quality Output: Both offset and web presses produce professional-looking cards with sharp details and accurate color reproduction.

- Speed and Efficiency: These machines are designed for mass production, churning out thousands of cards per hour.

- Durability: The printing process creates robust cards that can withstand countless shuffles and deals.

Disadvantages:

- High Cost: The initial setup costs for plates and equipment can be prohibitive for small-scale projects.

- Complexity: Operating these machines requires specialized training and experience.

- Limited Customization: These methods are best suited for large, standardized print runs, like over 500 decks.

The Home Game: Printing for Hobbyists and Small Businesses

For those looking to create custom playing cards in smaller quantities, several alternative printing options exist:

- Digital Printing: This technology uses a toner or inkjet process to directly apply the design onto card stock. While convenient and versatile, digital printing might not offer the same level of detail or color accuracy as offset lithography. Additionally, the cost per card can be higher, especially for larger print runs.

- High-End Home Printers: Modern inkjet and laser printers can handle cardstock, allowing for creating small batches of cards at home. However, limitations exist in terms of print quality, card durability, and the ability to handle thicker cardstock.

Advantages:

- Affordability: Digital printing and high-end home printers offer a more budget-friendly entry point compared to industrial presses, suitable for decks under 500 sets.

- Customization: These methods are ideal for creating unique, one-off designs.

- Accessibility: Digital printers and some home printers are readily available for purchase by individuals or small businesses.

Disadvantages:

- Lower Quality: The output might not match the vibrancy and detail of industrial printing.

- Limited Durability: Cards printed digitally or on home printers might be more susceptible to wear and tear.

- Volume Limitations: These methods aren't ideal for mass production due to higher costs per card and slower printing speeds.

Setting Up and Calibrating for Success

Regardless of the chosen printing method, proper setup and calibration are crucial for achieving optimal results. Here's a general overview:

1. Software and Design: Ensure your design software is compatible with your chosen printer and that your card design meets proper size and bleed specifications.

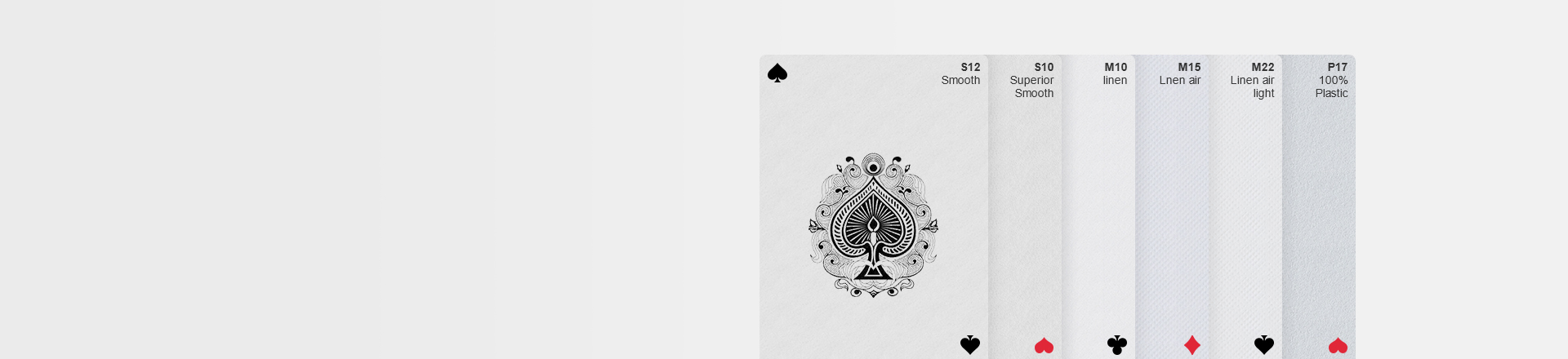

2. Media Selection: Choose high-quality cardstock specifically designed for playing cards. Consider factors like thickness, finish (glossy or matte), and compatibility with your printer.

3. Printer Settings: Select the appropriate printing mode based on your cardstock (e.g., cardstock, high-quality paper). Adjust color settings for optimal vibrancy and accuracy. Some printers offer specific profiles for playing card printing.

4. Calibration: Regularly calibrate your printer's colors using a calibration device and software. This ensures consistent color reproduction across print runs.

Testing and Quality Control: Ensuring Your Cards Are Top Deck

Once your printer is set up, it's vital to test print quality and color accuracy before committing to a large print run. Here's how:

1. Test Prints: Print a small batch of cards on your chosen cardstock using the planned settings.

2. Visual Inspection: Carefully examine the printed cards for any defects like blurring, streaking, or misaligned colors.

3. Color Accuracy: Compare printed colors to the original design on a calibrated monitor. Consider using a color checker to assess.

Solving Common Printing Problems: Keeping Your Cards Out of the Muck

Even with meticulous preparation, printing issues can arise. Here's how to tackle some common problems:

1. Color Inaccuracy:

- Cause: Miscalibrated printer, incorrect color profile, low-quality ink/toner.

- Solution: Recalibrate your printer, ensure you're using the correct profile for your cardstock and printer model, consider switching to higher-quality ink/toner cartridges.

2. Bleeding and Misalignment:

- Cause: Incorrect bleed settings in the design, printing issues with the press.

- Solution: Double-check your design's bleed settings to ensure it extends beyond the final cut line. If using industrial presses, consult with the printing service provider to address alignment issues.

3. Banding and Streaking:

- Cause: Clogged print heads, low ink/toner levels, uneven paper feed.

- Solution: Perform a print head cleaning cycle as per your printer's instructions. Replace empty ink/toner cartridges. Ensure the cardstock is feeding smoothly through the printer.

4. Fading and Smudging:

- Cause: Low-quality ink/toner, improper drying time after printing, touching the printed cards before they dry completely.

- Solution: Use high-quality inks/toners formulated for cardstock. Allow printed cards sufficient drying time before handling. Consider using a setting spray specifically designed for printed materials.

5. Warping and Curling:

- Cause: Incorrect cardstock selection (e.g., too thin), improper storage conditions (e.g., high humidity).

- Solution: Invest in high-quality, playing card-specific cardstock with a higher grammage (weight). Store printed cards in a cool, dry environment with minimal humidity fluctuations.

Choose Acelion as your card manufacturer, where our standard automated design templates help you avoid issues such as low resolution, insufficient bleed, and improper sizing. As an experienced playing card printer, we all use high-quality, environmentally friendly materials. Our technical team can quickly identify and correct problems during production, ensuring you steer clear of common printing issues.

Beyond the Basics: Advanced Techniques for Playing Card Printing

For those seeking to elevate their playing card printing game, here are some advanced techniques:

- Varnishing: Applying a protective varnish can enhance durability, improve water resistance, and create a more professional finish. Different varnishes offer matte, glossy, or even textured finishes.

- Foiling and Embossing: Adding metallic foil accents or textured embossing effects can create visually stunning and unique playing cards. These techniques are often used for premium decks or special editions.

- Die-Cutting: Die-cutting allows for creating custom-shaped playing cards, adding a unique touch to your design. However, this technique requires specialized equipment and expertise.

- Security Printing: For decks involving collectible cards or those used in competitive gaming, security printing features like microprinting or invisible inks can be incorporated to deter counterfeiting.

Conclusion: From Humble Stock to Royal Flush

Playing card printing, though seemingly straightforward, involves a fascinating interplay of technology, design, and craftsmanship. By understanding the various printing methods, their advantages and disadvantages, and the importance of setup, calibration, and quality control, you can ensure your playing cards are not just functional but visually stunning and built to last. Click on our shopping page and start printing your own playing cards now!

Relevant

- Blog

- Creative Ideas for Artist Trading Cards: 30 Unique Inspirations

- Specialty Paper Guide: 4 Powerful & Stunning Types That Impress

- Top 20 Modern Card Deck Ideas To Strong Custom Printing

- Online Card Maker: 5 Powerful Free vs Paid Features to Save Big

- 20 Creative Board Game Ideas to Spark Fun & Learning

- 5 Environmentally Friendly Game Card Packaging Solutions

- A History of the Tarot: From Card Game to Cosmic Symbolism

- Creative Playing Cards: 5 Bold Design Inspirations

- How Custom Corporate Cards Enhance Branding and How They Are Made

- Why And How To Design Your Own Flashcards?

- The Magnetic Charm of Cardistry: A Modern Art Form's Enduring Appeal

- 290gsm Italian Black Core Vs 300gsm Japan Black Core: A Deep Dive into Premium Playing Card Materials

- The Art Of Shine: A Complete Guide To Foil Printing In Playing Card Design

- Remembering Complex Tarot Spreads With Custom Instruction Booklets

- Packaging For Your Playing Card Box: Shrink Wrap vs. Cello Wrap

- Modern Innovations In Playing Card Design: A New Era Of Creativity And Functionality

- The Spade Symbol: The Origins And Inspirations Behind Playing Card Design 1

- The Ultimate Color Psychology Guide to Print Promotional Playing Cards 2

- Choosing the Best Online Playing Card Printer

- 10 Innovative Tips For Crafting Effective Marketing Playing Cards

- Use Canva To Create Print-Ready Playing Card Files

- Online Card Printing Checklists: Mastering Print Perfection

- Advertising Playing Cards Myths: Use Them To Maximize Your Business Growth

- How To Choose An Online Custom Playing Card Website 1?

- The Booming World Of Custom Card Game Market

- Waterproof Elements: A Dive into Plastic Playing Cards

- How to Customize Playing Cards: Interview From The Card Designer

- Playing Card Deck Printing for Prototypes and Limited Editions

- Playing Card Size: Design Overview And Guide

- Dealing Up Fun: A Guide to Card Games for Kids

- Dealing Up Fun: A Guide to Card Games for Adults

- How To Make Playing Cards #3: Specifications To Print Playing Cards

- How To Make Playing Cards #2: Elements About Designing Playing Cards

- How To Make Playing Cards #1: Techniques To Design Playing Cards

- Coolest Playing Card Designs That Cut a Figure In 2024

- How To Design For Tarot Brands And Astrology Tarot Cards

- Tarot Color Symbols: 12 Important Colors In Tarot Cards

- Card Game Design: 4 Playing Card Design Ideas

- The Hidden Worlds: A Journey Through Tarot Card Back Designs

- A Shuffle Through 2024: Popular Playing Card Designs

- How To Design And Make a Window Tuck Box For Playing Cards?

- Playing Cards Drawing Ideas And Design Inspiration

- From Paper To Plastic: What Are Playing Cards Made Of?

- How To Make Flashcards: A Comprehensive Guide For Effective Flashcards

- How To Make Tarot Cards Out Of Playing Cards?

- Create Any Design And Make Playing Cards At Acelion Playingcards

- How To Play Poker For Beginners 1: Hearts And Spades Card Game

- How To Play Poker For Beginners 2: Speed And War Card Game

- Designs Of Playing Card Suits: A Dive Into The Markings Of A Deck

- Color Psychology in Playing Card Design: Beyond Red and Black

- Number Typography and Readability For Playing Cards Design

- 10 Card Game Design Blogs And Websites To Explore

- Understanding Tarot Card Designs: Core Principles and Significance

- Card Deck Design: Customization and Personalization

- Custom Playing Cards: Regional Variations In Playing Card Design

- Finding Your Ideal Tarot Card Manufacturer: A Step-by-Step Guide

- POD Compliance and Legal Considerations For Trading Card Game

- April Fool's Day and the Fool Tarot Card: A Curious Juxtaposition

- Face Cards Evolution 1: The Design Journey of Playing Card Courts

- Face Cards Evolution 2: The Design Journey of Playing Card Courts

- Hierarchy Of Poker: A Guide To Poker Hand Rankings

- Printing Services vs. DIY Printing: The Great Debate For Custom Playing Cards

- Printer Compatibility: Laser, Inkjet Or Offset For Playing Cards Printing?

- Playing Card Packaging Options: Protect and Present Your Decks in Style

- Tarot Printing: Choosing High-Quality Images

- The Role of Technology in Creating Custom Game Cards

- How To Choose An Online Custom Playing Card Website 2?

- Creative And Fun Uses For Trading Cards: Beyond The Basics

- Why And How To Fully Custom Game Cards Both Sides?

- Why And How To Fully Custom Game Cards Both Sides?

- Playing Card Printing: Equipment, Setup, and Troubleshooting

- The Ultimate Guide To Black Core Cardstock: Durability, Options, And Iconic Decks

- The Ins and Outs of Custom Playing Card Materials and Finishes

- 5 Money-Saving Tips (With Custom Cards) For Small Businesses

- The Art of Special Finishes: Elevating Custom Cards with Unique Touches

- 6 Essential Considerations When Selecting the Ideal Online Card Printer

- Copyright Guidelines for Game Card Designers

- Discover The Advantages Of Printing Cards With AcelionPlayingCards.Com

- Why You Need to Choose a Good Font for Your Game Cards

- The Ultimate Color Psychology Guide to Print Promotional Playing Cards 1

- 10 Essential Factors To Consider When Designing High-Quality Playing Cards

- Mastering Spades Playing Cards: The Most Popular Questions Answered

- How Many Cards Should You Design For Custom Card Decks?

- The Best Teacher Gifts for Anytime of Year: Flash Cards and Board Games

- Playing Cards: Icons Of Pop Culture And Their Fascinating Journey

- The 5 Benefits of Playing with Custom Game Cards

- Educational Benefits of Custom Memory Game Cards: Enhancing Cognitive Development Across Age Groups

- Debunking 6 Tarot Card Myths And Beginner Tips For Tapping Into Your Intuition

- Print-Ready Tarot File: Enlarge the Image

- Top 7 Most Discussed Topics By Playing Card Creators

- 5 Steps To Craft A Hit Card Game

- Managing Dies for Card Printing Precision: A Masterclass in Craftsmanship

- The Timeless Deck: Rediscovering the Relevance of Paper Playing Cards in the Digital Age

- The Spade Symbol: Unraveling the Origins and Inspirations Behind Playing Card Design 2

- Cardstock Options For Custom Playing Cards: An Order Guide

- The Uses of Playing Cards: A Journey Through History and Versatility

- How To Solve Difficulty In Shuffling With The Right Playing Cardstock And Finishes?

- Acelion Playing Card's Environmental Commitment: For a Greener Tomorrow

- Why Choose China For Custom Card Printing From Acelion’s Insights

- Use Jumbo Playing Cards To Solve Difficulty In Playing With Large Groups

- What Caused The Explosion In Custom Tarot Decks?

- Design Wedding Playing Cards as Unique Guest Gifts with POD Services

- 10 Creative Playing Card Inspirations That Will Blow Your Mind

- Effortless Custom Corporate Playing Cards: 1 Design & Production Guide

- Wedding Playing Cards: 54 Romantic Ways to Tell Your Love Story

- Wedding Poker Cards: 10 Stunning Theme Design Ideas

- Custom Corporate Playing Cards: Amazing Boost in 2025

- Wedding Poker: Unlock 5 Powerful Customization Trends

- Custom Corporate Poker: 7 Stunning Ideas to Amplify Branding

- Online Card Maker: 5 Powerful Ways to Boost Holiday Sales

- Online Card Maker Trends 2025: Bold AI & AR Innovations

- Creative Poker Ideas: 5 Stunning, Happy Custom Gift Decks

- Custom Playing Cards: 5 Successful Industries That Thrive

- DIY Game Cards: 5 Exciting Ways Online Tools Transform Creativity

- Custom Poker Cards: 5 Powerful Ways to Boost ROI & Brand Love

- Custom Wedding Playing Cards: 10 Fun, Engaging Games for Epic Joy

- 20 Creative Wedding Favor Ideas Your Guests Will Love

- 18 Creative Corporate Promotion Ideas to Boost Your Brand

- Meeting Minimum Order Quantities: A Solution for Independent Artists and Small Businesses

- How to Publish Your First Tarot Deck: A Step-by-Step Guide for Creators

- How to Manage Your Game Card Printing Design: A Comprehensive Guide

- 5 Tarot Books You Should Read In 2025

- Cardstock Options For Custom Playing Cards: An Order Guide

- The Art Of Deception: The Magic Of Playing Cards In Cinema

- POD Playing Cards Trends in 2025: Print & Design Insights

- Why Is Playing Cards Important?

- 7 Experiences in Designing Game Cards: A Game Designer’s Journey

- 10 Unique Oracle Decks You Can Create for Spiritual Growth and Inspiration

- The Magic of Customization: Why Personalized Game Cards Outshine the Rest

- Card Game Accessibility and Customization: Making Games Welcoming and Personal

- 10 Ways Publishers Can Support Their Playing Card Decks

- The Cost of Playing Card Printing: Why Metallic Stamping Is So Expansive?

- Narrative Game Card Design: Weaving Stories Through Cards

- Engaging Flashcard Designs: Fun Ideas and Customizable Templates

- Science-Based Flashcard Design: Proven Techniques for Maximum Retention and Learning

- 15 Creative Uno Customizable Cards Ideas for Fun Gameplay

- Custom Quote Cards: 5 Stunning Ways to Inspire Your Next Project

- Custom Quote Card Ideas: 10 Creative Designs for Any Occasion

- Make the Playing Cards Near Me in USA: 10 Best Picks You’ll Love!

- 20 Inspirational Quotes for Printable Quotes Cards

- DIY Playing Cards: 52 Bold Ways to Tell Epic Brand Stories

- Make the Playing Cards Near Me UK – 10 Powerful Options Reviewed

- Positive Quotes Card Printing: 15 Strong Inspires with Custom Designs

- Life Quotes Card Printing: 20 Inspiring Designs to Elevate Joy

- Success Quotes Card Printing: 7 Inspiring Designs to Empower You

- Ace of Spades Card: 5 Powerful Reasons It Still Dominates

- How to Play Dominoes: 7 Brilliant Tips to Instantly Win More Games

- Quote Of The Day For Work Card Printing: 10 Powerful Ideas

- Playing Cards on Demand: 7 Powerful Reasons Creators Love Acelion

- Cute Quotes Card Printing: 12 Powerful Phrases to Boost Sales

- Fathers Day Card Idea: 20 Powerful & Heartwarming Designs

- Mothers Day Card Ideas: 20 Heartfelt & Powerful Gift Picks

- Aesthetic Quotes: 12 Stunning Ideas for Powerful Card Printing

- Print on Demand Tarot Cards: 7 Powerful Reasons to Start from Acelion

- Birthday Card Ideas: 13 Brilliant Ways to Create Unforgettable Joy

- 15 Valentines Day Card Ideas That Truly Wow & Inspire

- Make the Playing Cards Near Me in Japan: 10 Best Powerful Picks

- Online Card Maker: 7 Powerful Tips to Avoid Costly Mistakes

- Online Card Maker: 7 Powerful Benefits for Small Biz Success

- Creative Playing Cards: 7 Powerful Reasons Collectors Love Them

- Personalized Deck of Cards: 10 Powerful Reasons to Love It

- Eco Card Printing: 7 Powerful Reasons to Go Gree

- Gloss vs Matte: 7 Powerful Reasons to Choose the Right Finish

- POD Playing Cards: 5 Powerful Answers to Avoid Costly Mistakes

- Symbolism of Cardology: 10 Powerful Secrets You Should Know

- Customize Luxurious Playing Cards: 6 Powerful Reasons Why You Should Try

- Custom Card Games: 10 Powerful Ways for Positive Success

- Thank You Card Ideas: 5 Powerful Creative Tips That Inspire

- Poker Anti-Counterfeiting: 5 Powerful Ways to Avoid Fake Cards

- Sustainable Game Cards: 7 Powerful Benefits You Should Know

- Custom TCG: 8 Powerful Reasons for Massive Success

- Playing Card Back Design: 6 Powerful Tips for Stunning Success

- Trading Card Copyright: 8 Shocking Risks & Powerful Tips

- Creative Poker Gameplay: 7 Exciting Powerful Ideas